REQUEST A FREE ESTIMATE!

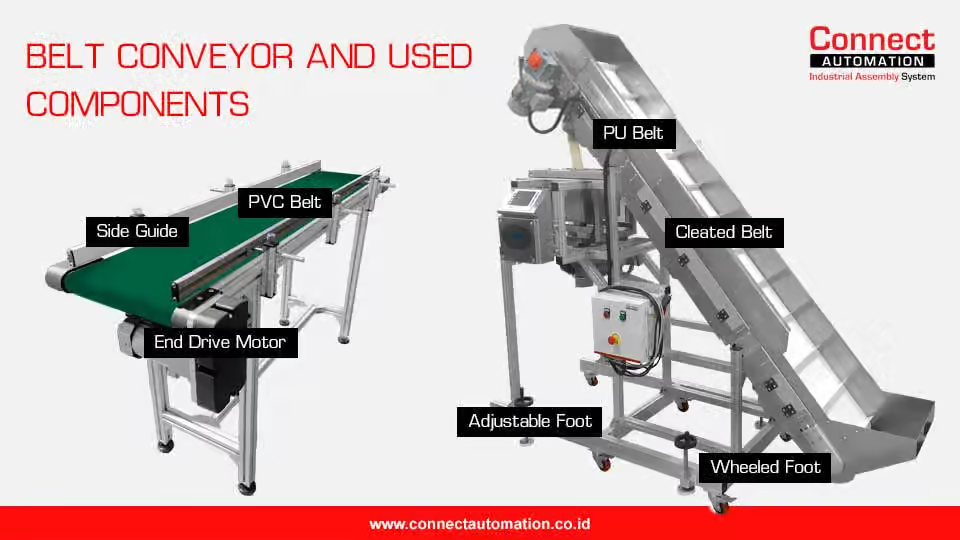

Belt Conveyor and Its Important Components

Conveyor has lots of variants which can be differentiate easily just by looking at its shapes. A more traditional conveyors are belt conveyors and roller conveyors while a more modern ones are modular conveyor and table top chain conveyor.

Belt Conveyor Definition

Belt conveyors are conveyor machines that utilizes a belt as the media for transferring items. Each belt conveyors usually have a motor that is intended to rotates the roller drive attached tightly to the belt so the belt would move following the roller drive rotation. A belt conveyor has 2 types of roller, one is a roller drive which is attached to the belt conveyor's motor, then the second is the roller idler which is attached to the other end of the belt conveyor (that doesn't have a motor).

Belt Conveyor Uses

In Indonesia alone, many industries are already utilizing belt conveyors. This is because belt conveyor supports many types of product transfer. The downside of a belt conveyor lies on its belt which can be torn and majorities of belt types are not food grade. There are lots of supplier or manufacturer of belt conveyor in Indonesia especially in larger cities such as Jakarta and Surabaya.

Components of Belt Conveyor

Every type of conveyors have their own conveyor components have its own functionality. There are several conveyor components that are shared throughout multiple types of conveyor and there are some conveyor components that are specifically used for one type of conveyor. Conveyor components used in multiple types of conveyor have the same functionality even though they are installed in different type of conveyor.

-

Belt conveyors have several conveyor components available to choose from. Those conveyor components have their own characteristics and function. Some conveyor components are required such as the motor on a belt conveyor, and there are several conveyor components that are optional to use such as side guides. Here are a list of some conveyor components that are used by belt conveyor in Indonesia:

- Belt is a sheet that is used as a media to carry items from one end to another end of a belt conveyor. Belt has many types and functions which can be selected specifically to the needs of each industry

- Roller is a cylinder which commonly found on both ends of a belt conveyor. Both rollers are wrap tightly with a belt so when the roller rotates, the belt would rotates along the roller.

- Ladder or main frame of a belt conveyor is placed between both rollers (hence is located within the belt). Ladder is also initended to hold the weight of items on top of belt conveyor and also to maintain the distance between the two rollers so the belt wouldn't lose tension.

- Motor used by a belt conveyor to move the belt and commonly placed in one end of a belt conveyor. Motor can be assembled in 3 different areas of a belt conveyor.

- Legs of a belt conveyor are vertical frames that allows the belt conveyor to stand. Some types of belt conveyor legs consist of a rubber underneath it that can dampen dynamic load such as vibration.

- Cleat or fins on a belt is a sort of barriers attached along the belt. Cleat is usually used on an incline or decline belt conveyor so the items wouldn't fall over or to give consistent space between items.

- Side wall is a wall attached to both sides of a belt and along the belt which acts as a barrier so the items wouldn't rolls out of belt area and fall. Usually used in an incline or decline belt conveyor.

- Slot cover is an accessory that can be used in an aluminium belt conveyor. These slot covers are intended to close all unused slots of an aluminium profile, so the belt conveyor wouldn't gather dust or dirt inside the slot.

- Side guide acts as a guidance railing so the items stay on top of the belt conveyor. Side guides shaped straight while a side wall usually have a corrugated shape which can't be use to guide items. Side guide is attached on the side of the main frame while side wall is attached directly on the belt.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps