The Ultimate Guide To Center Drive Conveyors And Its Benefits

What are the Different Types Of Conveyors Drive?

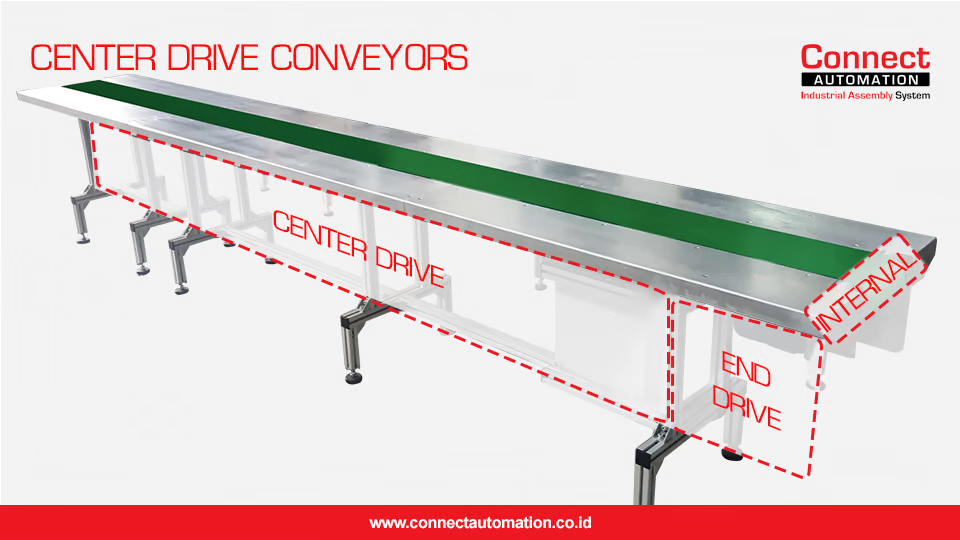

Conveyors are used to transport materials from one point to another in a safe and efficient way. Depending on the type of application, conveyors have different types of drives. End drive conveyor, center drive conveyor, and internal drive conveyor are the most common types of drives used in various industries.

End drive conveyors are, just like the name said, positioned the drive of conveyor at one of the end of the conveyor, while center drive conveyor puts the motor at the center of (or anywhere along) the conveyor. These 2 types of conveyor drive assembled the motor externally. Unlike these 2 conveyor drive types, an internal drive conveyor put its drive inside the roller pulley, or more concisely, the roller pulley and the drive is assembled into one component.

What Is A Center Drive Conveyor And How Does It Work?

A center drive conveyor is a type of conveyor system that uses motorized drive at the center of (or along) the conveyor to move materials. This type of conveyor is used in many industrial applications, such as sorting, packaging, and assembly lines. The center drive works just like the other drive types. It would rotate (drive) the roller pulley that would also move the belt along the conveyor.

Benefits Of Using A Center Drive Conveyor In Your Manufacturing Process

Center drive conveyors are becoming increasingly popular in the manufacturing industry due to the numerous benefits they offer. A center drive conveyor allows integration with other machines that usually is impossible using an end drive conveyor. Center drive conveyors allow both ends of the conveyor to be put inside another machine if needed by the production process. Lack of space is generally also one of the reason why industry uses a center drive conveyor. Center drive conveyors put its drive underneath the conveyor to avoid adding width size to the conveyor dimension (as the case with end drive conveyor). Center drive conveyor is also known for better handling a dual direction conveyor.

Get FREE consultation with our sales engineer team!

Appoint a Consultation

How To Choose The Right Conveyor Drive Type For You?

Each conveyor drive type has their own benefits and usually a design process for a conveyor needs an on-the-spot survey so conveyor manufacturer can design the best conveyor for an industry. This is to match the amount of space available to the needs of the industry. For the best result, we recommend you to always consult to your conveyor manufacturer before purchasing one.