REQUEST A FREE ESTIMATE!

Several Parts Of Conveyors And The Use Of Each One

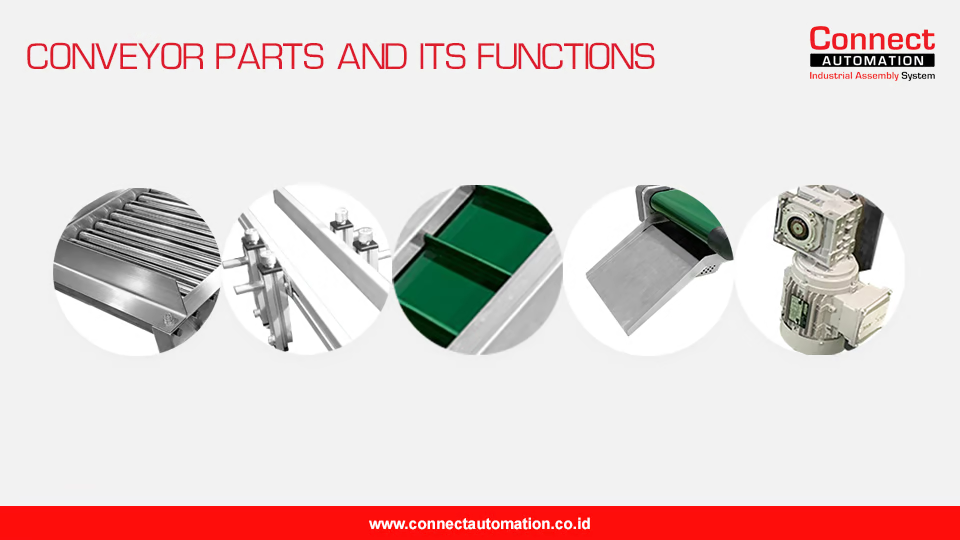

A belt conveyor system consists of two or more pulleys (often also referred to as drums), connected by a conveyor belt in a closed loop that rotates around them. Within one system, there are various conveyor components that are integrated with one another to ensure the material handling process runs efficiently and stably.

To operate optimally, a belt conveyor is equipped with various conveyor components such as electric motors, idlers, drive units, skirt boards, belt cleaners/scrapers, covers, and supporting structures. Each conveyor component has a specific function that supports the overall system. Below are the key parts of the system along with the conveyor components and their functions:

- Belt (Conveyor Belt)

The belt is one of the main conveyor components that functions as the medium for carrying material from the starting point to the destination. Conveyor belts can be made of rubber, fabric, PVC, PU, or metal, depending on the type of material and application requirements. - Pulley (Drum)

The pulley is a conveyor component that plays a role in driving and maintaining belt tension. It consists of a drive pulley and a tail pulley. The drive pulley is connected to the motor to move the belt, while the tail pulley helps maintain belt tension and belt tracking direction. - Motor and Drive Unit

The electric motor provides power to rotate the drive pulley. The motor can be AC or DC, usually paired with a gear reducer to control speed and torque. It is mounted on a motor bracket and supported by a counter bearing for stability. - Idler (Support Roller)

Functions to keep the belt flat and support the load of the conveyed material. Common types include garland idlers (flexible roller sets), return idlers (supporting the return belt), and impact idlers (absorbing impact during loading). - Skirt Board (Loading Skirt)

A retaining panel installed on the sides of the loading area to prevent material from spilling off the conveyor belt during loading. - Belt Cleaner or Scraper

Used to clean leftover material sticking to the belt after the discharge point, preventing buildup and maintaining conveyor performance. - Structure or Stringer

The supporting frame that holds all conveyor components in place, ensuring rigidity and stability. - Side Guide or Centering Device

Keeps the belt and products aligned on track, preventing misalignment during conveyor operation. - Conveyor Cover (Tudung)

The conveyor cover is a protective conveyor component that encloses the top part of the conveyor to protect materials from rain, heat, or dust, while also maintaining workplace safety.

Additional Conveyor Types

In addition to conventional belt conveyors, there are several other conveyor types used depending on industrial needs:

- Table Top Chain Conveyor

Uses a flat chain (table top chain), available in straight or flexible side-flexing versions for curved paths. Example: Rexnord NH45 Series Polymeric Table Top Chain, commonly used in beverage, pharmaceutical, and packaging industries due to its space-saving design and ability to maintain product orientation. - Modular Plastic Belt Conveyor

Utilizes interlocking plastic segments that form a modular belt. Suitable for heavy-duty, accumulation, and sharp-edged or high-load materials. Usually made of lightweight, durable, and impact-resistant polycarbonate material. - Truck Loader Conveyor

Designed to facilitate loading and unloading materials to/from trucks. Typically available as gravity or telescopic conveyors with adjustable height for various truck sizes. Often uses a 20” Chevron belt with a load capacity of about 1–50 kg per foot. Available in manual/gravity and electric types for more precise control.

Each conveyor component works together to ensure safe, efficient, and long-lasting operation. Proper selection of materials, design, and maintenance significantly affect the performance and lifespan of conveyors in manufacturing and logistics industries.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps