REQUEST A FREE ESTIMATE!

Guide To Choose Gear Box and Motor Type For A Conveyor

Conveyors are machines that help move items from one point to another automatically and continuously. Usually, the parameters that are sought in a conveyor are maximum load capacity and the speed of the conveyor. Some industries requires a fast conveyor, some requires a slow conveyor or even the combination between fast and slow conveyors within the same production line. This difference in speed is managed by the use of appropriate gear box.

Gear box function is to help manage a speed that it gets from a motor. Things that uses a gear box are conveyor, car, bicycle and other things that require a change in torque or speed.

The gearbox itself is a power transfer system whose function is to channel engine power or power to other engine parts. With the aim that these components can produce a movement either by shifting or turning. Gear boxes can be used to help regulate the speed obtained from a motor. Objects that use gear boxes are conveyors, cars, bicycles and other objects that require changes in torque or speed.

Load capacity that a conveyor can support and the speed of the conveyor are 2 related things. If the conveyor supports heavier load capacity then it would have slower speed, and vice versa. Load capacity and conveyor speed are affected by 2 components, the conveyor’s motor and gear box.

Here are some of the components that are in the conveyor gearbox:

- Drive motor The drive motor is a component that generates power to drive the conveyor. Commonly used drive motors for conveyors are electric motors, diesel motors, and wind motors.

- Pinion gear The pinion gear is the first gear that receives rotation from the drive motor. Pinion gears usually have a smaller number of teeth compared to other gears.

- Bevel gear Bevel gear is a gear that functions to change the direction of rotation of the pinion gear. Bevel gear usually has a triangular shape.

- Gear drive Gear drive is a gear that functions to forward the rotation of the bevel gear to the conveyor shaft. Geae drives usually have a larger number of teeth compared to pinion gear and bevel gear.

- Shaft Shaft is a shaft that functions to forward rotation from the gear drive to the conveyor.

- Bearing Bearings are components that function to support the shaft and reduce friction between the shaft and other components.

- Casing The casing is a housing that serves to protect the gearbox components.

- Lubricator Lubricator serves to lubricate the gearbox components so that they can work properly.

- Cooling System Cooling system serves to cool the gearbox components so that they can work more durable.

- Safety device Safety devices function to protect gearbox components from damage, such as overload protection and thermal overload protection.

- Pinion Gear Pinion Gear is a gearbox that has a gear arrangement with a function as a direct main drive gear. Pinion Gear receives rotary motion from the drive motor which is then forwarded to the Bevel.

- Bevel Gear One part of the gear in the gearbox. Serves to receive rotating force from Pinion Gear and forward to other gears in the gearbox. Bevel Gear has more Pinion Gear in it because it is still one part.

- Neck Gear One gear that is widely used by industrial machines is Neck Gear. Its function is to connect the rotation from the drive to other components. Usually mounted on a roll calender shaft, which is integrated with the clutch and drive motor.When the drive motor rotates, the Neck Gear will rotate. This rotation will later be connected to other gears that have been installed on the roll calender shaft. That way, all roll calenders rotate in balance because between the Neck Gear and others are integrated in the gear groove.

- What is the total weight of items that you wish to bet put on top of the conveyor?

- How fast would you want your conveyor be?

The gearbox itself has various types and different functions. The following are the kinds of gearboxes used in industrial needs:

Conveyors can move without using a motor but instead use other sources of drive such as the force of gravity used in decline / gravity roller conveyors. If the conveyor does not use a motor, but instead uses another source of drive, then the use of a gear box on the conveyor is not required.

Here are several questions that you would be getting from your conveyor supplier:

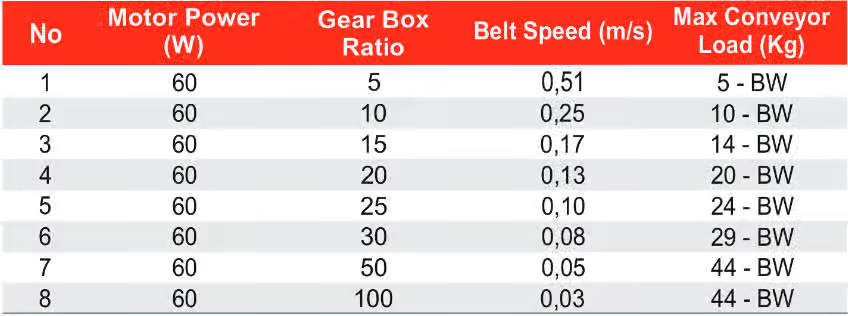

These two questions will be asked to help your conveyor supplier to determine type of motor, motor capacity and the gear box to be used. Motor specifications that affects load capacity and conveyor speed are motor type (1-phase or 3-phase) and motor power (using Watt as unit of measure on a 1-phase motor and Kilo Watt on a 3-phase motor), while the gear box specification that affects it is the ratio of the gear box.

As you can see in the image above, by using a motor with the same power, the larger the gear box ratio means the slower the conveyor speed is and the higher the load capacity that the conveyor supports.

Get FREE consultation with our sales engineer team!

Appoint a Consultation

Make sure the selected gearbox is of good quality so that it can work optimally and last long.

Still confused about choosing the right conveyor? Contact our Sales Engineer to consult directly according to your needs. Connect Automation is committed to providing the best service and quality. As one of the conveyor companies in Indonesia, we are ready to realize your dream conveyor. Contact us now!

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps