PT. Environeer

031-99858624 (Surabaya), 021-8935060 (Jakarta)

REQUEST A FREE ESTIMATE!

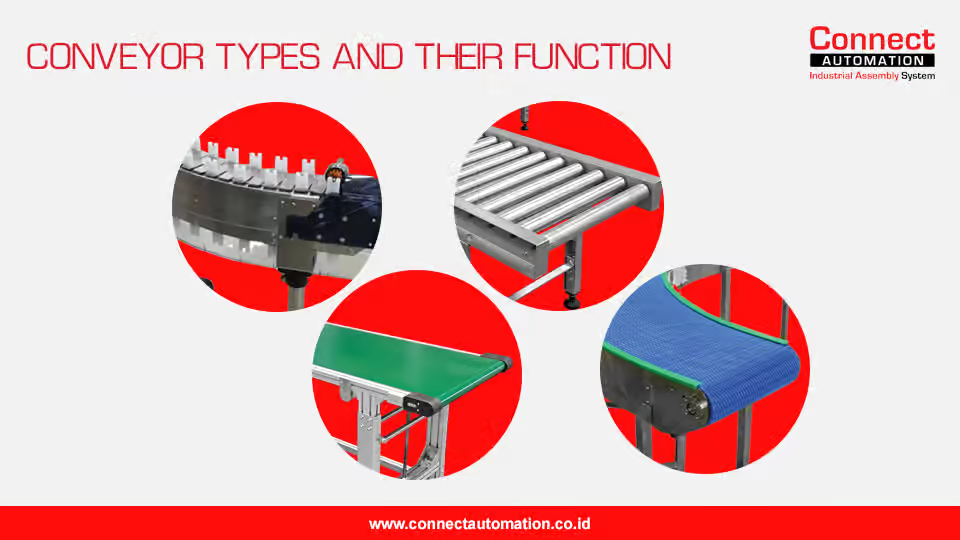

General Information On Conveyors Types and Their Uses

A conveyor is a material handling system used in various industries to move products quickly, efficiently, and safely. There are many types of conveyors designed for specific needs, ranging from classic belt conveyors to air-based or chain-driven automated systems. Choosing the right type of conveyor depends on material characteristics, capacity, speed, and working environment conditions.

- Belt Conveyor

The most common and versatile type of conveyor. It is used to transport bulk materials or packaged products over short to medium distances. The belt can be made of PVC, PU, rubber, or food-grade materials and is suitable for logistics, food, and light manufacturing industries. - Roller Conveyor

Uses a series of rollers to move flat-bottomed items such as cartons, pallets, or boxes.- Gravity Roller Conveyor: uses gravity, ideal for areas that do not require power

- Powered Roller Conveyor: rollers are motor-driven to control speed or direction, ideal for automated systems

- Screw (Auger) Conveyor

Uses a rotating helical screw blade to move bulk or powder materials horizontally or at an incline. Commonly used for flour, cement, sand, or grains. - Aero-Mechanical Conveyor

Transfers light and fragile materials using cables and discs within an enclosed tube. Ideal for abrasive or delicate materials requiring gentle handling. - Pneumatic Conveyor

Uses a pressurized airflow to transfer bulk materials through pipes or tubes. - Chain Conveyor

Utilizes steel or plastic chains to move heavy or large products such as pallets, drums, or automotive components. - Cable Conveyor

Similar to an aero-mechanical conveyor but uses a flexible cable to carry discs or carriers. Suitable for fragile materials that require gentle transfer over long distances. - Modular Plastic Belt Conveyor

The belt is made from interlocking plastic segments that can follow straight or curved paths. Used for product accumulation, heavy loads, or materials with sharp edges. - Cleated Belt Conveyor

Equipped with vertical cleats or partitions on the belt to prevent products from slipping when moving on inclined or steep paths. - Curved Belt Conveyor

Allows the belt to move along curved paths, useful for optimizing space in corners or narrow areas. - Inclined Belt Conveyor

Designed to transfer products between different height levels, such as from a lower floor to an upper floor or vice versa. - Bucket Elevator Conveyor

Uses small buckets to vertically lift bulk materials. Commonly used for grains, fertilizers, coal, or mining materials.

Don't know what conveyor to buy? Have some specifications to discuss?

Get FREE consultation with our sales engineer team!

Appoint a Consultation

Get FREE consultation with our sales engineer team!

Appoint a Consultation

Each type of conveyor has its own function, capacity, and advantages. Selecting the right system will improve production efficiency, workplace safety, and minimize operational costs.

About Us

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Cikarang Office

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Surabaya Office

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps