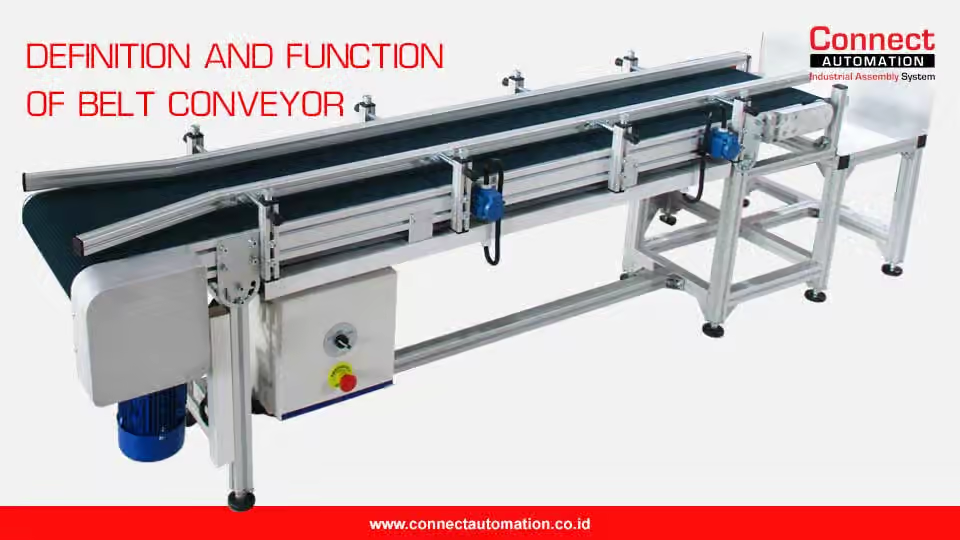

Definition and Function of Belt Conveyor

Definition of a conveyor is machines or tools that are used to move items in large quantity continuously from one end of conveyor (start) to the other end of conveyor (end). Definition of conveyor can be separated based on the conveyor type, conveyor function and the material used for making the conveyor itself, but nevertheless the core definition of a conveyor as a whole is as stated above. Definition of conveyor is a machine that is used to move items from one point to another.

Belt is a sheet that surrounds conveyor from one of the end to the other end. The function of a belt is to act as a moving container to transport every items that are placed onto the belt from one conveyor end to the other. In addition, it can transport bulk materials from small to medium-sized chunks (e.g. coal). There are many belt material such as PVC, PU, mesh and others. PVC belt is the most commonly used type of belt while PU belt is a belt that is safe to transfort food, chemicals, medical tools or other items that require high hygiene.

Belt conveyors are basically machines that are used to assist workers by carrying and moving solid objects in large quantity. The use of belt conveyors are really common in industrial area because in residency area, people just don't move items in large quantity as in industrial area and therefore it's very rare to see residents having a belt conveyor in their home. Belt conveyors usually used to carry and move solid objects such as packaging, food and beverage, spareparts, utensils and more.

Definition of Belt Conveyor

The definition of a belt conveyor is a tool to assist workers on finishing tasks. Belt conveyors have a lot of specification that allows belt conveyors to transport solid objects with varieties of characteristic such as hot, oily, sharp and more.

Belt conveyors are used to move objects in large quantity and heavy objects. In industrial area, belt conveyors are highly needed to move product or raw materials from one place to another. Besides being fast and easy, belt conveyors can save manpower required to move the products.

Functions of Belt Conveyor

The thing that differentiate other types of conveyor is how belt conveyor move items using its belt. Belt conveyors have a belt that works to receive products and to move them.

Belt conveyor supports production processes that are more specific besides its basic function to move items. Some production processes that are supported by using a belt conveyor are:

-

Sorting

Some production processes requires a fast and automatic product sorting process. Belt conveyors are used alongside another tool such as a sensor to separate good and bad products. So that it can minimize the existence of products that are not in accordance with standard procedures mixed in decent products, or it can be said that it can facilitate the Quality Control (QC) process. In other words, Belt Conveyors can help your company improve production standards well, without having to increase labor.

-

Packing

Product packaging is very important for the industry, especially in the FMCG (Fast Moving Consumer Good), food, and harmaceutical sectors. Because packaging is used to label and maintain the quality of the product in good condition until it reaches consumers. If there is a mistake in choosing food product packaging, the quality of the product will be not good. Belt conveyors can be used within packaging process so products that needs to be packaged come faster to the worker who does the packaging. This packaging process is also supported by the use of carton sealer.

-

Cooling

Hot products that just came out of processing can be cooled with a specific belt conveyor. This cooling process is usually supported by cavities on the conveyor belt which allows air current to pass through. To further reduce the cooling process, belt conveyor can be run alongside blowers directed straight to the belt conveyor. In other words, Belt Conveyor can be used to help the cooling process so that it can summarize time and be able to increase the productivity of your company.

-

Distributing

Belt conveyors can also be used to send products from processing machines to another machines in one production process. This removes the process of manually lifting products onto the belt conveyor by manpower. One of the most common functions of conveyor belts is to help the process of shipping goods from one place to another. For example, in the process of transporting mining materials and construction materials such as coal and cement. In addition, the distribution and storage process will also be helped by the presence of a conveyor belt. This tool will make it easier for workers to move goods to be stored in warehouses or sent to certain posts.

-

Labelling & Printing

Product labelling can be supported by belt convenyors so that people can print label faster onto the product packaging with the use of tools such as printers. Labels that usually goes to the packaging are expiry date and product name label. Conveyor belts make it easier for employees to label your products. Its fast and efficient process can also help summarize time so that you can reach production targets quickly.

-

Weighing

Products moved using belt conveyors can also be weigh automatically. This is done by using a sensor, weighing scale and ejector. Products are to be stopped on top of the weighing scale and if product weigh outside of standard weight then an ejector would push the product off the belt conveyor. This can make it easier for you to carry out the Quality Control (QC) process with predetermined standards. So, you no longer need to re-check and don't need to worry about errors in production.

Parts of the Belt Conveyor

-

Pulley Rope

Useful for carrying material and continuing the rotating force. The strength of the belt is not seen based on its thickness, but on the number of reinforcing layers (ply) and tensile stress per ply (Tensile Strenght). Viewed from the structure of the reinforcing layer.

-

Snub Pulley

Used to increase the contact winding angle between the pulley and the belt. Usually the snub pulley is located near the drive pulley.

-

Internal Belt Cleaner

Equipment used to clean the side of the belt from residual material that is not poured out during loading and remains attached to the side of the belt.

-

Impact Idler

Located in the area of material spillage into the Belt. Made of Rubber (rubber) which functions as a barrier to the impact load of material that falls on the Conveyor, so as to reduce belt damage.

-

Return Idler

Or it can be called a belt support roller in the unloaded area mounted on thebottom of the frame.

-

Belt

The part that functions to receive transfer of motion energy from the rotating Pulley, the belt will transport material from one end of a conveyor belt construction to the other.

-

Bend Pulley

Serves as a bend or change the direction of the belt. Where the Bend Pulley works to adjust the balance of the belt on the ballast.

-

Takeup Pulley

Fungsinya digunakan untuk mengencangkan_belt, sehingga dapat menjaga kekencangan belt sama antara sisi yang tidak membawa material dan sisi yang membawa material. Take up pulley juga dapat memberikan tegangan pada belt pada start awal.

-

Takeup Unit

Its function is used to tighten the belt, so that it can maintain the same belt tension between the side that does not carry material and the side that carries the material. Take up pulley can also provide tension on the belt at the initial start.

-

Carriying Roller Idler

Serves to keep the belt on the burdened part or as a roll supporting the tireloaded with material. The position of the Carrying idler is on the conveyor table

-

Pulley Cleaner

Serves to clean the pulley from dirt or residual material that falls when transported.

-

External Belt Cleaner

Serves to detect and ensure that the conveyor will remain clean. That way the conveyor will have the opportunity to live longer with less downtime due to damage.

-

Head Pulley

Serves for the initial drive in a conveyor system.

-

Feed Chute

inlet of goods to be moved by the conveyor. The goods to be moved are put into the feed chute before being on the conveyor.

-

Skirt Board

Serves as a partition that is attached to the right and left of the belt at the loading place, usually made of metal or iron which can be mounted upright or tilted which serves to prevent scattered loads.