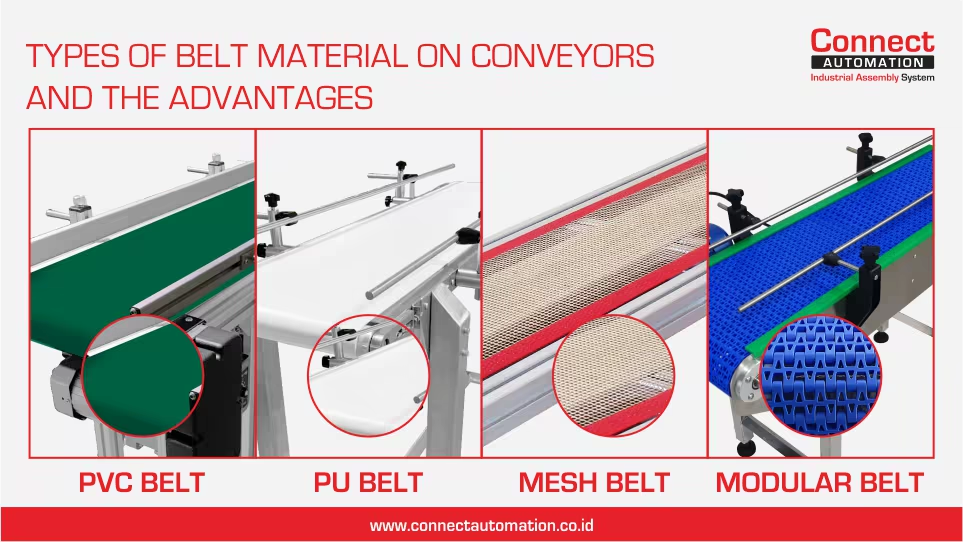

Types of Belt Materials on Conveyors and Their Advantages

Each industry must use the material and type of conveyor belt according to its use in each production line. For example, food and beverage production must use a conveyor belt that is safe for food or food grade. So it is important for you to know and understand the various types of materials, uses and types of conveyor belts. Here are some conveyor belt materials and their applications.

Belt conveyors are highly efficient and commonly used material transportation systems in various industries. One of the most important components of a conveyor is the belt, which is responsible for the transfer of material from one point to another. Various types of belt materials are available, each with its own advantages and uses. In this article, we will get to know some of the types of belt materials in conveyors and the advantages they have.

PU Conveyor Belt (Polyurethane)

This type of belt is needed by the food and beverage industry, because the conveyor belt with PU material is a food grade type that is safe when in direct contact with food. From this, the PU Belt type is often found in the food, frozen, cosmetics and other industries. Apart from that, this type has strong tear resistance, good elasticity, resistance to certain impacts, has good water resistance, and can survive well even in humid conditions. The selling price for this belts is relatively expensive, but in the long term, conveyor belts made of polyester material will be more economical. This belt can be recognized if it has a white color and is used in the FNB industry.

PVC Conveyor Belt (Polyvinyl Chloride)

This type of belt has a dark green color, has a more competitive price. PVC belts wear out more easily and are not as strong when subjected to impacts. It can be concluded in general that PU belts are more durable and long-lasting than PVC belts. This type of belt in industry is usually used to transfer goods such as cardboard, packaging or other goods, which do not come into direct contact with the finished material.

Plastic Interlocking Belt (Modular Belt)

Modular belt conveyors should be familiar, and are quite often found in several industries. Usually the industries that use this conveyor are the pharmaceutical industry, cosmetics industry, and several F&B industries. Modular belts are cheaper in maintenance costs than PVC or PU conveyor belts. This is because if damage occurs to the modular conveyor belt, there is no need to change all one belt, just replace the damaged part with a new part. Apart from that, the modular belt is made from food grade materials. Often used in industries that require a fairly high level of sterility and are safe for chemicals.

Mesh Conveyor Belt

This belt is designed to allow air flow and the remaining liquid in the product does not stick to the belt. This mesh belt has quite high heat resistance, namely up to 2000 Celsius. Mesh belt conveyors are usually used in the automotive industry. The automotive spare parts industry requires conveyors that are resistant to high temperatures and are not easily damaged when exposed to oil.

Metal Conveyor Belt

Based on the different manufacturing methods, metal conveyor belts are divided into several types, such as diamond mesh belts, trapezoidal metal mesh belts, ball mesh belts, u-chain mesh belts. This belt material has the advantages of high temperature resistance, wear resistance, corrosion resistance, high tensile strength and long service life. Stainless steel belts are the most widely used among metal conveyor belts.

Conclusion

The selection of the type of belt material on the conveyor must be based on the specific needs of the use and operational conditions. The advantages of each type of material can provide an optimal solution according to industry needs. With the right selection, the conveyor will work efficiently, reliably, and make a positive contribution to the company's productivity and operational efficiency.

Connect Automation, the first choice of conveyor solutions for your industry. As a leading conveyor manufacturer in Indonesia, we deliver superior quality and competitive prices. Trust your operational sustainability to us, because we not only provide conveyors, but also the best solutions to improve efficiency and productivity in your industry. Buy Now!