Minimum and Maximum Slope Angle on a Conveyor

Maximum and Minimum Angle on a Conveyor

Conveyors are not only used to move products from one point to another, but also are used to move products from one elevation or height to another elevation. Conveyors with slope angle can be separated into 2 types based on the direction of transfer, an incline conveyor or decline conveyor. Incline conveyors are conveyors that are used to move products from lower elevation to a higher elevation, while a decline conveyors are used to move products from higher to lower elevation. There are some industries that needs a conveyor that can be both decline and incline conveyor. Industries that needs incline/decline conveyor usually needs it for loading-unloading produced goods from a warehouse to a truck or vice versa.

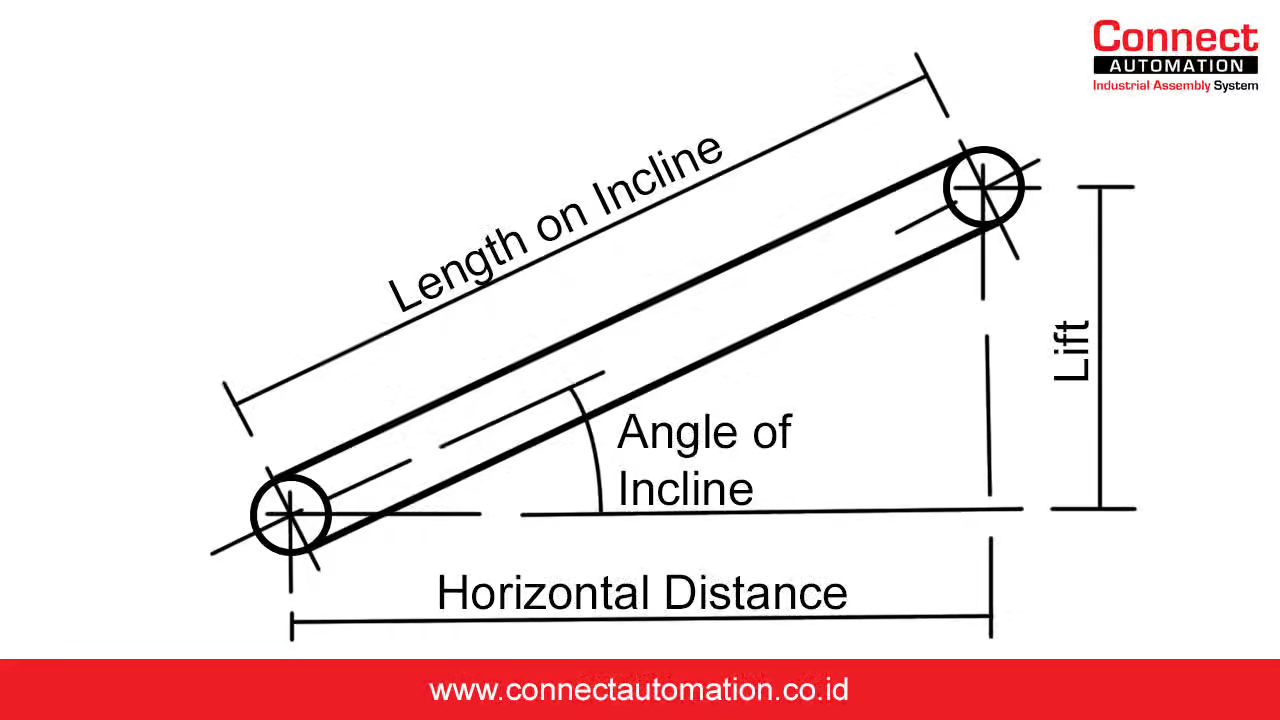

These incline and decline conveyors are used widely across many fields of industry. When you need a conveyor with incline or decline system, you would have to understand whatever things that you need to consider before planning to designing your own conveyor. Incline and decline conveyor will always require an slope angle. This slope angle is a vital factor in an incline or decline conveyor system. Incorrect slope angle could cause the products to slip or fall over causing the conveyor to be ineffective in moving products.

Slope angle of a conveyor can be calculated using the height difference between start and end point of a conveyor and also the length of conveyor. Slope angle will determine the height of each legs along the conveyor. Slope angle is different according to the type of product moved, the type of conveyor and the belt type used. There are many type of conveyors that can be used to move products using incline or decline.

Belt Conveyor

Belt conveyor is a type of conveyor that is commonly used as an incline and decline conveyor. Belt conveyor have a high enough friction or friction coefficient, so there are more type of products that can be moved, this includes granule-type products.

-

We have several recommendations for incline / decline belt conveyor:

- Maximum slope angle of 20° without the use of cleat

- Slope angle can exceed 20° by using additional cleat accessory or using a bucket for vertical conveyor, such as the bucket elevator, steep incline conveyor, side wall conveyor or pocket belt conveyor

-

An incline / decline belt conveyor have several types such as:

-

Incline/Decline Belt

Incline / decline belt conveyor is a belt conveyor that have a slope shape without any horizontal / flat conveyor area

-

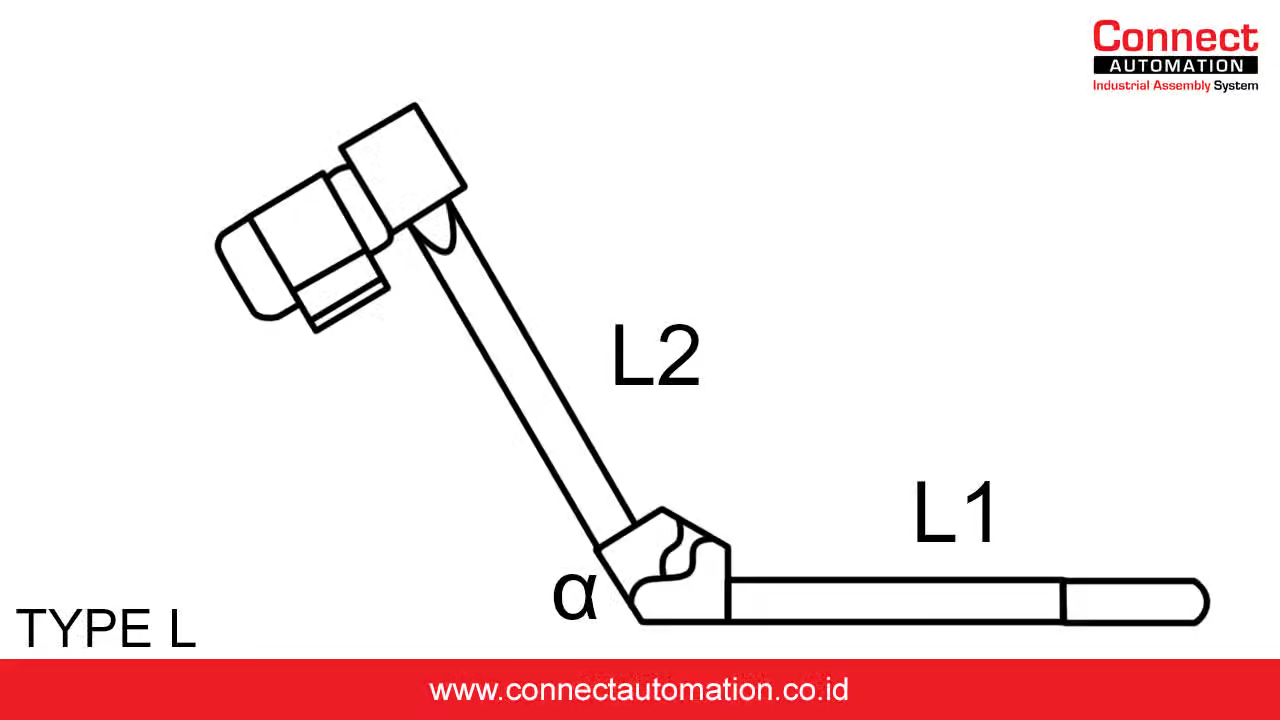

L-Incline Belt

L-Incline belt conveyor is a type of incline / decline belt conveyor that have a flat area on the bottom of the conveyor. L-Incline is commonly used because its flat area can be made flush with another conveyor or connected to another machine. L1 length depends on your needs while L2 length depends on specified slope angle.

-

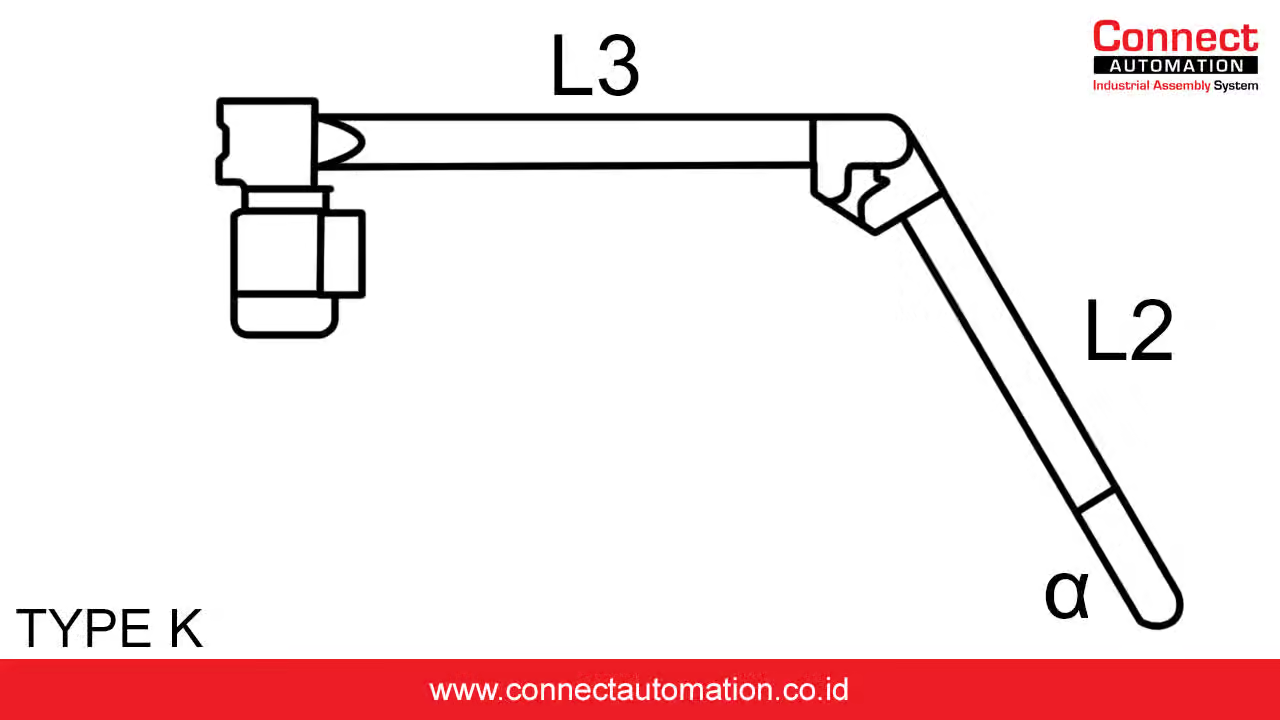

K-Incline Belt

K-Incline belt conveyor is a type of incline / decline belt conveyor that have its flat area on top of the conveyor. K-Incline belt conveyor can also be used as a decline belt conveyor that connects its flat area to another conveyor or another machine. L3 length depends on your needs while L2 length depends on the slope angle.

-

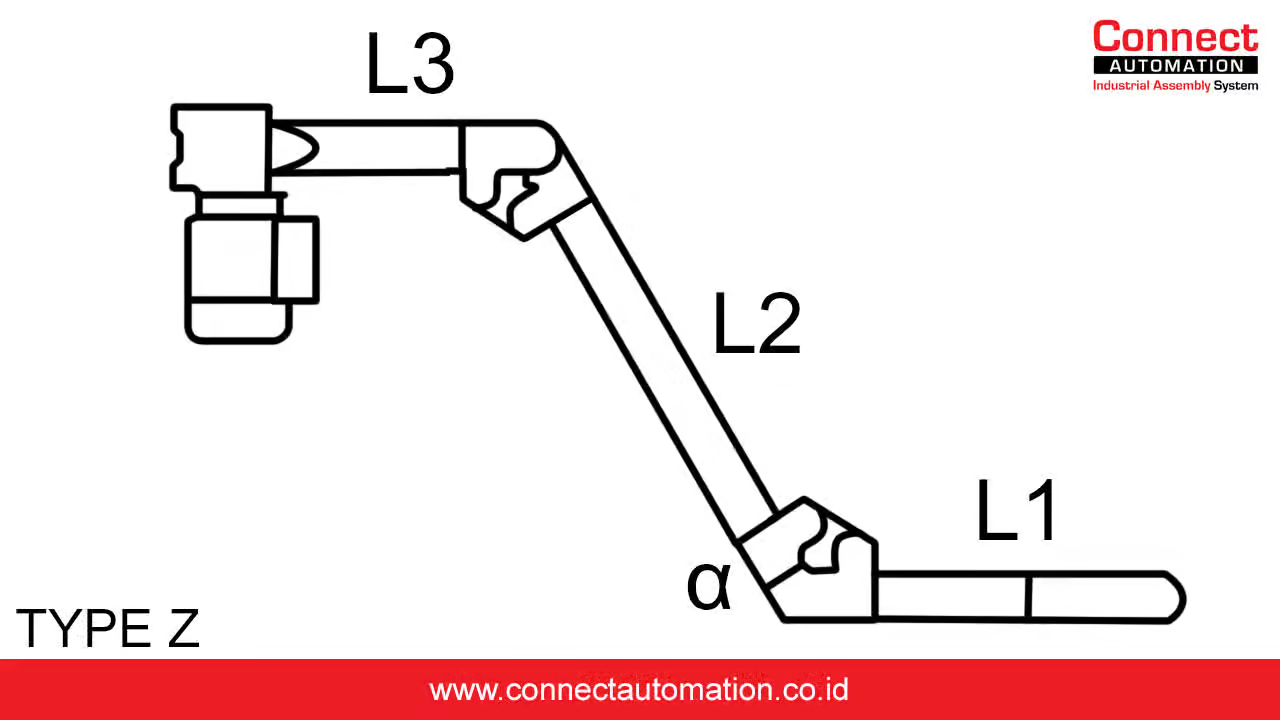

Z-Incline Belt

Z-Incline belt conveyor is an incline / decline belt conveyor which have 2 flat areas on the top and bottom of the conveyor. L1 and L3 length depends on your needs while the L2 length depends on slope angle. If the L1 and L3 sides should be flush with another conveyor or machine, then you need the Z-Incline belt conveyor

These are Connect Automation’s projects using different type of incline belt conveyor:

Roller Conveyor

Roller conveyor that commonly used, that have an slope angle is gravity roller conveyor. Gravity roller conveyor is a roller conveyor that uses gravitational force, which is usually used to move products from higher to lower point. Gravity roller conveyor is commonly used for connector between conveyor or a loading-unloading conveyor for packaged produced goods

-

We have several recommendations for gravity roller conveyor:

- Slope angle for gravity roller conveyor is 5° at minimum, with every 1000 mm of length reduces height by 100 mm

- The commonly used width is from 300 mm to 600 mm

- The maximum length is 6000 mm, with the commonly used height is from 350 mm to 800 mm

- Products to be moved would have to have dimension that touches 4 rollers so it wouldn’t get stuck on the roller conveyor

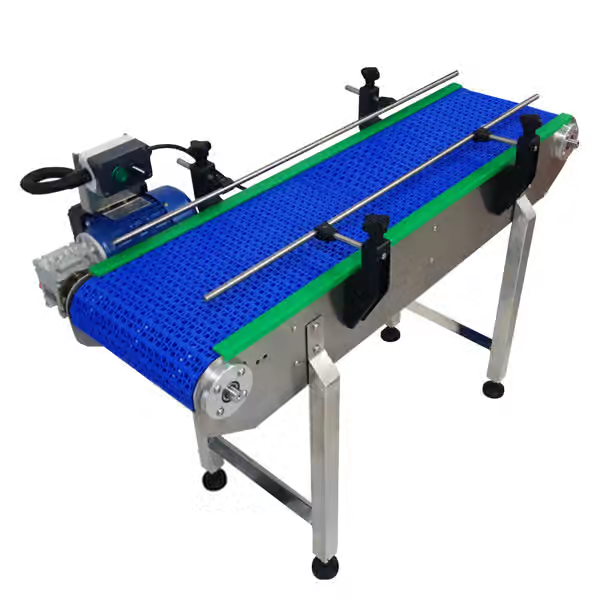

Modular Conveyor

Modular conveyor is a conveyor which belt consists of plastic modules combined into one belt using a join rod. Modular conveyor is becoming the best option for FMCG (Fast moving Consumer Goods) industries, because the down time is much faster when the belt is damaged. Modular conveyor can be used in food industry because the belt modules are proven for ISO as a food grade material. Modular conveyor can be used for incline or decline conveyor even though it’s rarely it.

-

We have several recommendations for modular conveyor:

- For incline conveyor, the motor is located at the highest end of the conveyor

- For decline conveyor, the motor is located at the lowest end of the conveyor

- Normal slope angle is 5°

- Using the accessory rubber top, the slope angle can reach up to 15° (adjusted based on the height and type of products)

Table Top Chain Conveyor

Table top chain conveyor is a conveyor which belt consists of plastic or stainless steel modules combined into one using a join rod. Table top chain conveyor can be designed to fit the shape of products, for example a bottle or cylindrical product, or any products that are tall and thin that needs to be moved in upright position. Table top chain conveyor is commonly used in beverage, cosmetic and pharmaceutical industries. Usually table top chain conveyor is used to move products horizontally and rarely designed to be incline or decline conveyor.

-

Kami menyarankan beberapa hal untuk table top chain conveyor incline / decline:

- For incline conveyor, the motor is located at the highest end of the conveyor

- For decline conveyor, the motor is located at the lowest end of the conveyor

- Maximum slope angle is 5°, more than that is not recommended because products moved would have a hard time keeping upright position.

- Using a rubber top accessory, slope angle can reach up to 15° (slope angle needs to consider the possibility of fallen products with the specified angle value)

Get FREE consultation with our sales engineer team!

Appoint a Consultation