REQUEST A FREE ESTIMATE!

Is It True That Using A Modular Belt Conveyor Saves Cost

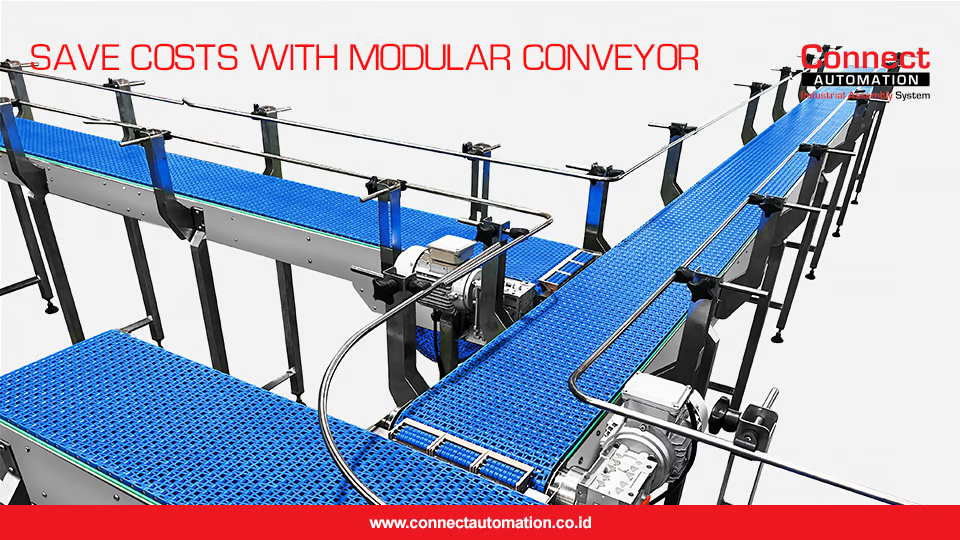

What Is A Modular Belt Conveyor And How Is It Different?

Modular belt conveyor is a conveyor that uses a belt to move goods from one of its end to its other end just like a traditional belt conveyor would. Then what’s the difference between a traditional belt conveyor and a modular belt conveyor? A modular belt conveyor uses a belt that is designed for modularity. Unlike a traditional belt, these modular belts are made out of small plastic modules that are combined together, using a joint rod, into a whole modular belt.

How Can Using A Modular Belt Conveyor Saves Me Money?

So first of all, let’s change the terms a bit. With conveyors, the word you use should be ‘investing’ not ‘spending’, and there are pretty good reasons why. Let’s go through them one by one. I’m pretty sure you’re going invest in a modular belt conveyor right after this article!

No More Manual Labor Moving Things Around

The great things about a conveyor are that they completely replace the need for manual labor to move your products around. If you have 1 person doing this manual labor, not only you would save the cost of the person’s labor, you would also save yourself time by moving the products faster and consistently using modular belt conveyor and also save yourself from a risk that might happen to the person during manual labor. With modular belt conveyor you would get consistency, reliability and faster process at once!

Your Food Products Can Directly Touch The Belt

Most modular belt conveyors use plastic materials that are proven by FDA for direct food contact. These materials are Polyethylene (PE), Polypropylene (PP) and Polyacetal (POM). If your industry requires certain level of hygiene then look no further than this modular belt conveyors. Don’t worry! Not only food & beverage industry that can use them, other industries can also use these modular belt conveyor to move their products.

Although this seems really good, but it still have the downside which is located in the belt material itself, which is plastic! As you know, plastic can crack and break under heavy pressure or abrasive environment, so be sure that you use modular belt conveyor for compatible product types. Mining industries can’t use modular belt conveyor as they use heavy-duty conveyors that have high resistance to high impact pressure and high load capacity overall.

Significantly Lower Maintenance Cost Than Belt Conveyor

Replacing a belt in a traditional belt conveyor requires a lot of process and will also take a lot of time to do it. With a modular belt conveyor, you only need to detach the damaged modular belt and then attach the new one and that’s it. Adjusting belt tension? No need. This lowers the duration of maintenance and get your production line going in no time.

Have I mentioned that you don’t need to replace the whole modular belt? If a traditional belt is torn, you would need to purchase a whole new belt then do all those process replacing it. With modular belt conveyors, you only need to purchase the plastic module that are damaged, replace it, then restart the conveyor like there’s never any damage.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps