REQUEST A FREE ESTIMATE!

CV40 and CV80 Belt Conveyor Understanding the Standard Difference

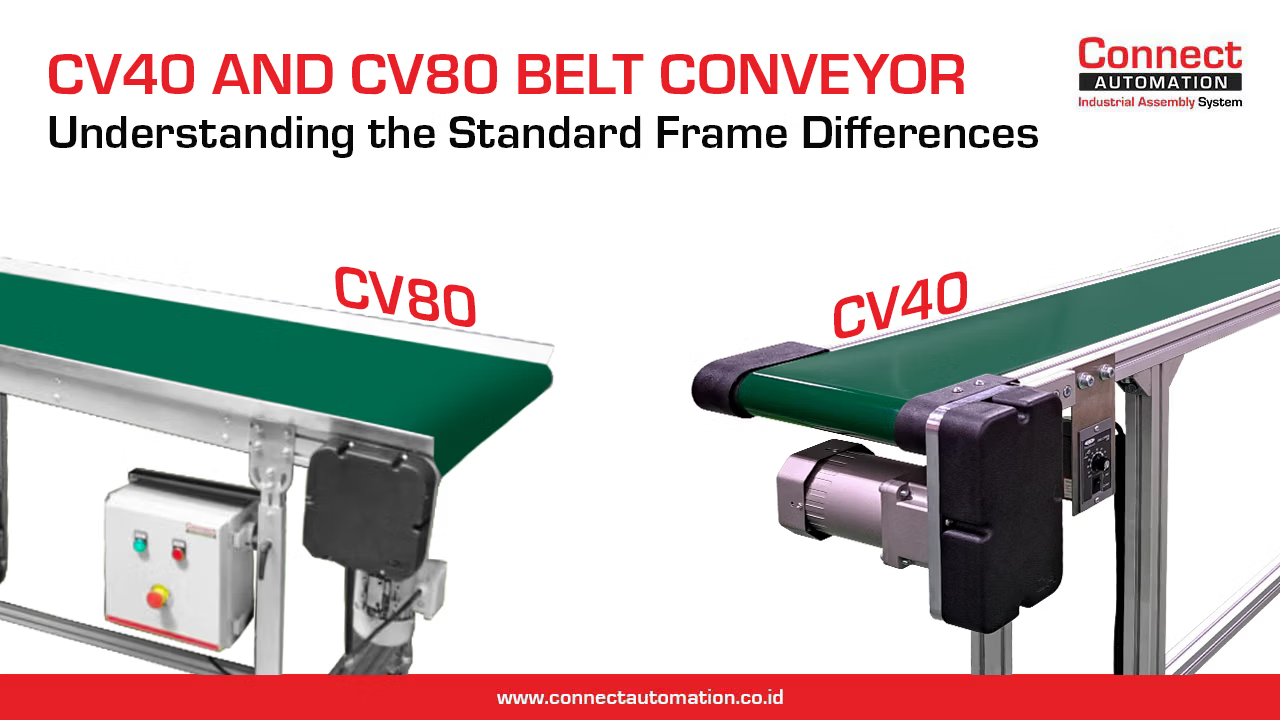

CV40 and CV80 Belt Conveyor: Understanding the Standard Frame Differences

In aluminium profile–based belt conveyor systems, structural consistency is essential to ensure performance, safety, and long-term reliability. To address different load classes and conveyor dimensions, our belt conveyor system is standardized into two main frame versions: CV40 and CV80. These standards are not defined arbitrarily. Each frame type is designed based on a direct relationship between aluminium profile size, roller diameter, motor specification, and conveyor dimensions. Understanding these differences helps users select the right conveyor configuration for their specific application.

Two Standard Main Frames for Aluminium Profile Belt Conveyors

Our belt conveyor systems are built using modular aluminium profiles, allowing flexibility while maintaining structural integrity. To accommodate different conveyor sizes and operating conditions, we define two standard configurations:

- CV40 – compact frame for light to medium duty applications

- CV80 – reinforced frame for medium to heavy duty applications

Each standard is engineered to match the roller size, motor type, and control system required for stable and efficient operation.

Aluminium Profile and Roller Size Relationship

CV40: Profile 4040 with Ø45 mm Rollers

The CV40 belt conveyor uses aluminium profile 40×40 (4040) as its main frame. This configuration is designed specifically to support rollers with a diameter of approximately 45 mm. This combination offers several advantages:

- Proper proportionality between roller size and frame structure

- Adequate rigidity for standard conveyor lengths

- Lightweight design without unnecessary overengineering

The CV40 frame is ideal for conveyors where compact dimensions and moderate loads are required, while still maintaining stable belt tracking and smooth operation. CV40 standard configuration: Profile 4040 + Ø45 mm rollers

CV80: Profile 4080 with Ø85 mm Rollers

For larger and heavier conveyor applications, the CV80 belt conveyor uses aluminium profile 40×80 (4080) as its main frame. This profile size is selected to properly support rollers with a diameter of approximately 85 mm. The larger roller diameter and wider profile provide:

- Increased structural rigidity

- Better load distribution along the conveyor length

- Improved stability for wide belts and long spans

This configuration is particularly important for conveyors that operate continuously or carry heavier products. CV80 standard configuration: Profile 4080 + Ø85 mm rollers

Structural Class and Application Scope

The difference in aluminium profile and roller size directly determines the application class of each conveyor standard.

CV40

- Light to medium duty applications

- Compact conveyor layouts

- Short to medium conveyor lengths

CV80

- Medium to heavy duty applications

- Large conveyor layouts

- Long conveyor spans and wide belts

By matching the structural frame to the application requirements, the conveyor system maintains optimal performance without excessive material usage.

Motor Specification by Conveyor Standard

CV40 Motor Configuration

CV40 belt conveyors are equipped with a single-phase (1-phase) motor. This motor type is suitable for:

- Light to medium loads

- Intermittent or standard production cycles

- Facilities with single-phase power supply

The motor selection aligns with the compact structure and operational scope of the CV40 frame.

CV80 Motor Configuration

CV80 belt conveyors use a three-phase (3-phase) motor, which offers:

- Higher torque capacity

- Better efficiency for continuous operation

- Improved performance under heavier loads

This motor type is commonly used in industrial environments where stability and durability are critical.

Conveyor Dimension Standards: Length and Width

To maintain structural integrity and operational safety, conveyor dimensions play a key role in determining whether CV40 or CV80 should be used.

CV40 Dimension Range

- Conveyor length: up to 6 meters

- Belt width: up to 600 mm

This range ensures that the 4040 profile and Ø45 mm rollers operate within safe mechanical limits.

CV80 Dimension Range

- Conveyor length: more than 6 meters, or

- Belt width: more than 600 mm

For conveyors exceeding these dimensions, the CV80 frame is required to prevent deflection, vibration, and premature component wear.

Speed Control System Differences

CV40 Speed Control

CV40 belt conveyors use a variable speed control unit. This system provides:

- Simple and reliable speed adjustment

- Easy operation for standard production lines

- Cost-effective control for basic conveyor applications

CV80 Speed Control

CV80 belt conveyors are equipped with an inverter (VFD). This allows:

- Precise speed control

- Smooth acceleration and deceleration

- Easy integration with PLC and automation systems

This level of control is essential for complex production lines and synchronized conveyor systems.

Why These Standards Matter

By defining CV40 and CV80 based on the relationship between roller size, aluminium profile, motor type, and conveyor dimensions, the conveyor system becomes:

- Structurally consistent

- Easier to specify and design

- Safer for long-term operation

- Clear and understandable for users and engineers

This standardization helps avoid underdesign or overdesign while ensuring each conveyor performs as intended.

Conclusion

CV40 and CV80 belt conveyors are designed to serve different industrial needs through clearly defined structural and mechanical standards. CV40 offers a compact and efficient solution for smaller conveyor applications, while CV80 provides the strength and stability required for larger, heavier-duty systems. By understanding these differences, users can select the right conveyor configuration that aligns with their production requirements, ensuring reliable operation and long-term system performance.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps