REQUEST A FREE ESTIMATE!

Small-Scale Conveyor for Packing, Sorting, and Internal Transfer

In many production facilities, packing, sorting, and internal transfer processes are still handled manually. Products are moved by hand, carts, or static tables. While this may seem simple, over time it often slows down workflow and creates inconsistencies in daily operations. This is where small-scale conveyors play an important role. Not mini conveyors, but industrial-standard belt conveyors designed for short-distance, repetitive processes. They are compact, easy to install, and ready to use without complex customization.

The Role of Small-Scale Conveyors in Production Areas

Small-scale conveyors are designed to support short but continuous workflows. Processes such as packing, sorting, and internal transfer do not require large or complex conveyor systems. Instead, they benefit most from conveyors that are practical, stable, and efficient. Thanks to their compact design, these conveyors can be installed in limited spaces without disrupting existing production layouts.

Conveyor Solutions for Packing Processes

In packing areas, unstructured product flow often leads to congestion and reduced operator efficiency. A small-scale belt conveyor helps ensure a smooth and consistent flow of products toward the packing station. This allows operators to focus on packing quality and speed, while the conveyor maintains a steady product movement. As a result, packing processes become more organized, faster, and easier to manage.

Conveyor Solutions for Sorting Processes

For sorting applications, small-scale conveyors enable products to move continuously through sorting stations. Operators can separate items based on size, type, or quality without repeatedly lifting or repositioning products. This approach improves efficiency, reduces handling errors, and helps maintain a consistent working rhythm, especially for daily production with stable volumes.

Conveyor Solutions for Internal Transfer

Internal transfers between processes—such as from a machine to packing, or from packing to storage—are often overlooked bottlenecks. Manual handling consumes time and increases operator fatigue. By using a small-scale conveyor, internal product movement becomes smoother and more controlled. Production flow feels more connected, organized, and easier to monitor.

Why Small-Scale Conveyors Are More Efficient

Not every production line requires a large conveyor system. Small-scale conveyors offer several practical advantages:

- Space-saving design, ideal for limited production areas

- Easy installation, without complicated setup

- Flexible configuration, adaptable to various layouts

- Cost-effective, suitable for growing industries

These conveyors are designed to function as ready components of a production system, not as time-consuming custom projects.

Operational Advantages in Daily Use

For packing, sorting, and internal transfer applications, small-scale belt conveyors are commonly equipped with single-phase motors. This makes power supply simpler, as they can operate using standard electrical sources already available in most facilities. In addition to easier installation, energy consumption remains efficient, helping keep operational costs under control for daily use.

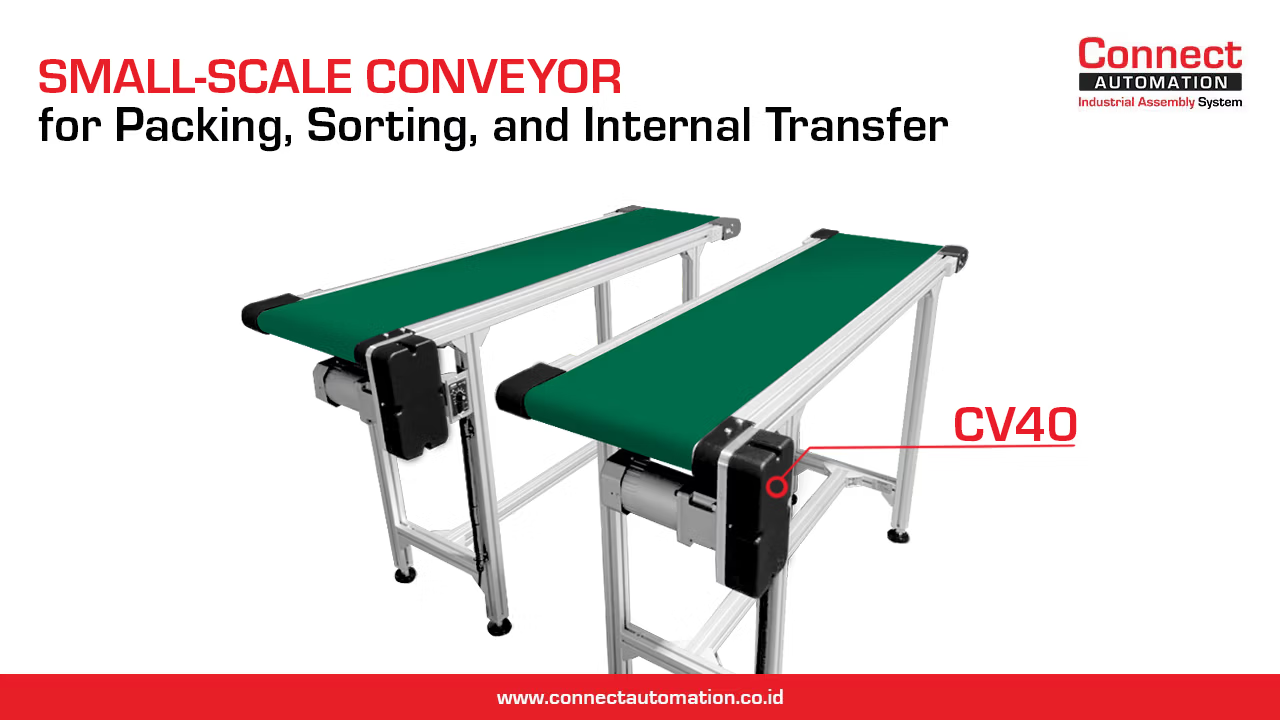

Example of a Small-Scale Belt Conveyor from Connect Automation

One example of a small-scale belt conveyor widely used for these applications is the CV40 from Connect Automation. CV40 is an internal product designation used by Connect Automation to represent a standardized small-scale belt conveyor designed for industrial use. The CV40 is available in various size options, allowing users to select the most suitable configuration without starting from a custom design. With its ready-to-use and plug-and-play concept, the CV40 from Connect Automation can be integrated directly into existing production lines. This standardized approach also makes it easy to replicate or expand conveyor lines when production capacity needs to grow.

Conclusion

For packing, sorting, and internal transfer processes, the most effective solution is not a large or complex system, but a well-standardized small-scale conveyor. With a compact footprint, industrial-grade construction, and easy installation, small-scale belt conveyors help production lines operate faster, cleaner, and more consistently. For manufacturers looking to improve efficiency without unnecessary complexity, small-scale conveyors provide a practical and reliable starting point.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps