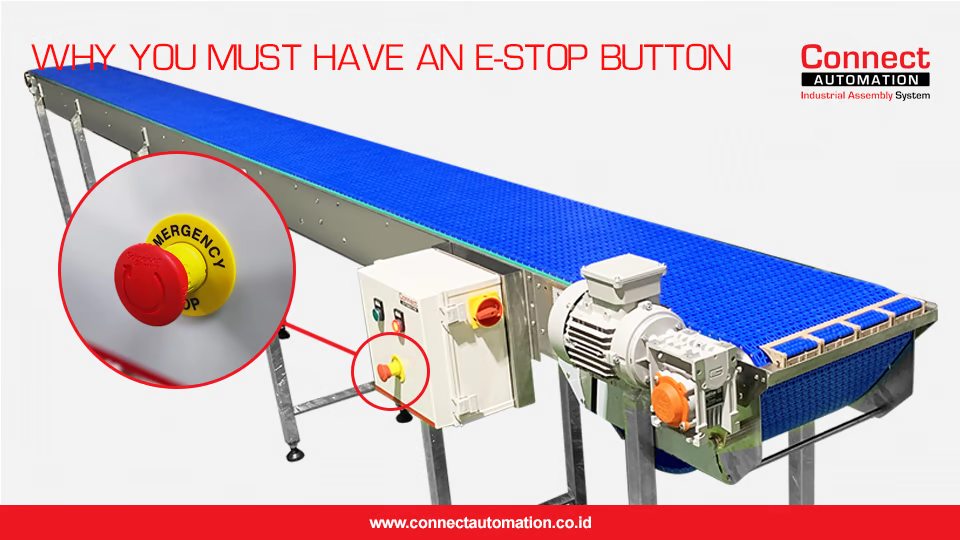

Reasons To Must Have An Emergency Stop Button On A Conveyor

What Is A Conveyor?

A conveyor is a machine that helps industries tremendously by moving products continuously and automatically with little effort from workers. A conveyor has several moving parts. These parts, for example, are the belt, bearing, gears and rollers to name a few.

These moving parts are a safety hazard when they are not covered. A standard practice for conveyors are to cover all moving parts so there’s nothing that can get pinched, crushed or cut by it. Connect Automation has list out many tips on working with a conveyor, including the do’s and don’ts.

What Is An Emergency Stop Button And Why Do You Need One?

An emergency stop button is required for all conveyors that possesses a posibility of safety hazards. Emergency stop button is, when pressed, will cause the conveyor connected to it to stop instantly. A conveyor is required to have at least one emergency stop button to stop it if emergency situation occurs. One emergency stop button can also be assigned for more than one conveyors, so if the emergency stop button is pressed, all conveyors connected to it would stop.

There are numerous reason on why you need to have an emergency stop button for your conveyor. The ultimate reason on why you would want to have an emergency stop button is for the safety of your worker. Governments also regulate the requirement of emergency stop buttons for industrial machineries.

To protect your worker safety is the one true reason on why you need to have an emergency stop button on your conveyor. No company would want any accidents happen to their workers, but unfortunately accidents do happen. Sometimes because of bad practice and some other times because of faulty system. The emergency stop button acts as a fail-safe so when the accidents do happen, the risk of worker injury would be reduced and thus as a company, your risk of covering the treatment cost for the workers would also be minimized

What To Do When the Emergency Stop Button Is Activated

Every company should create their own formal procedures when an emergency stop button is pressed. But, the main process would be similar to the following.

- When an emergency is occuring, press the emergency stop button related to the conveyor(s) to stop the conveyor(s).

- A call must be made to the emergency call number. This is to minimize the response time of the emergency services arriving to your location. If no injury occured, you may simply cancel the emergency call.

- If an injury did happen, take a look at the injury. If someone is stuck in one of the conveyor and is bleeding moderately, do not do anything until the emergency medical team arrived.

- After the situation has been successfully managed, you may start examining the related conveyor to determine whether any other object still jamming or any damages occured to the conveyor.

- Repair any damages and pull out any jammed objects inside it. Don’t forget to do Lock Out – Tag Out process before you do any maintenance.

- Investigate the root cause and determine what can be improved out of the conveyor (design-wise) to mitigate this issue in the future.

How To Install An Effective Emergency Stop System On Your Conveyors

Emergency stop buttons are the last safety net to ensure that injury-causing accidents do not occur in the work place. Choosing the placement of an emergency stop button requires a design process that should follow these, but not limited to, these guidelines.

- Emergency stop button(s) must be highly visible. Do not place emergency stop button under anything and if there are no proper lighting, use illuminated buttons instead.

- An emergency stop button must be within reach of the worker working with the conveyor. If a worker is often move along the conveyor, then some emergency stop buttons should be placed along the worker’s usual route.

- Emergency stop button(s) should not be covered by anything that would require additional steps to use it. If it is covered, then it must be opened before beginning operation.

- Make sure that there are not objects that could cover, jam or compromise the emergency stop button’s functionality when running the conveyor.

- Do not place emergency stop buttons near any button that have the same or similar color as the emergency stop buttons, which is the identical red and yellow.

Do not forget to check your emergency stop button’s functionality before working on any conveyors!