REQUEST A FREE ESTIMATE!

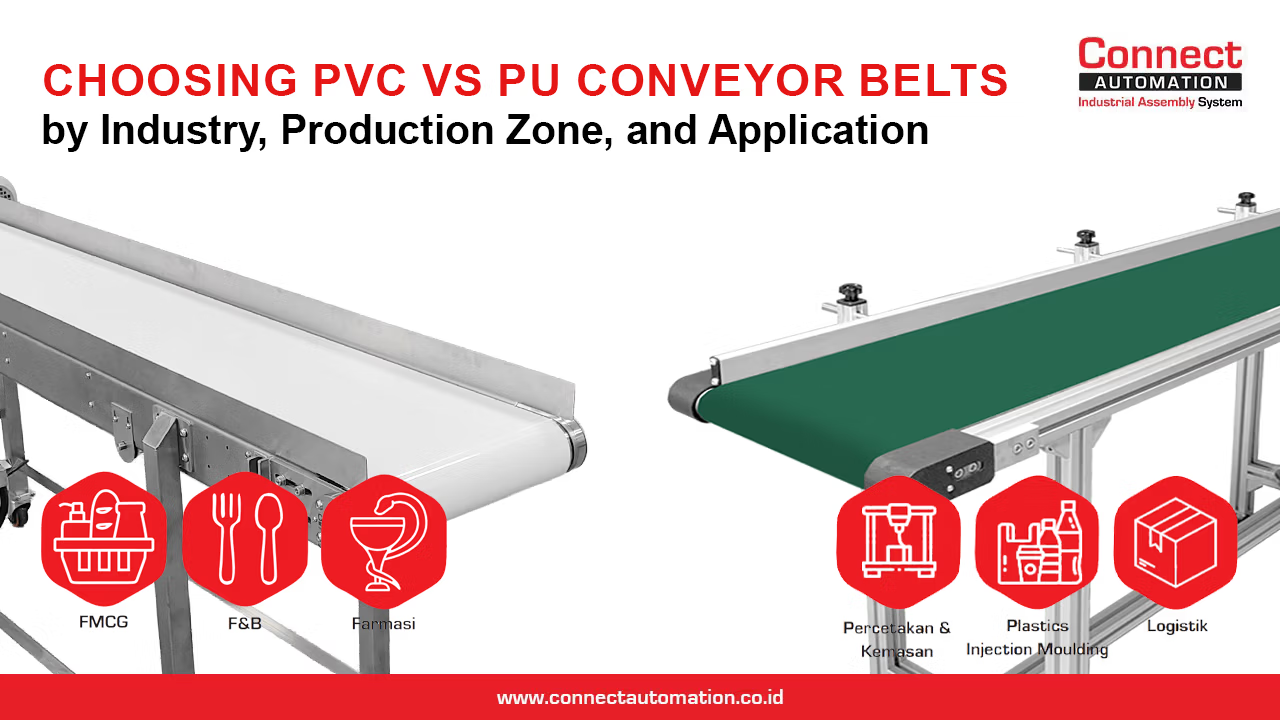

Choosing PVC vs PU Conveyor Belts for Industry Use

In modern industrial operations, selecting the right conveyor belt is not only about the purchase price per meter. The belt material you choose will directly impact production uptime, hygiene standards, belt lifespan, and long-term operating costs. Two of the most commonly used belt materials are PVC and PU/TPU. Both are widely applied across industries, but they serve different needs depending on:

- the type of industry

- the production zone or department within a plant

- sanitation and cleaning requirements

- the product being handled

- mechanical needs such as small pulleys, knife-edge transfers, or incline applications

This article provides a practical guide to choosing between PVC and PU belts based on industry sectors, then narrowing down to plant zones, and finally real-world use cases.

Quick Summary: PVC vs PU Conveyor Belts

Before diving into specific industries, here is a simple overview:

- PVC Conveyor Belts: more cost-effective, widely used for packaging, logistics, and dry product handling.

- PU/TPU Conveyor Belts: higher hygiene performance, better resistance to oils and fats, ideal for primary food contact and small pulley applications.

In many factories, both belt types are used simultaneously in different areas of the same facility.

1. Food & Beverage Industry

The food and beverage sector is one of the largest users of conveyor systems, as it requires fast product transfer while meeting strict hygiene standards. Primary Production Zones (Direct Food Contact) These areas include processes such as:

- cutting and trimming

- mixing lines

- forming and shaping

- conveyors after cooking and cooling

In these zones, the product directly touches the belt surface, meaning the belt must be easy to clean and safe for food contact. ✅ Recommended choice: PU/TPU belts Key reasons include:

- smooth, homogeneous surfaces that reduce contamination risk

- built-in resistance to oils and fats

- better suitability for frequent washdown and CIP cleaning

- edge sealing options that minimize harborage points

Secondary Packaging Zones (Product Already Wrapped) Once the product is sealed in primary packaging, hygiene demands decrease. ➡️ PVC conveyor belts are often the most economical solution Typical applications include:

- carton conveyors

- case packing lines

- accumulation conveyors for snack boxes

2. Bakery & Confectionery Industry

Bakeries have unique requirements, as many products are sticky and require close, precise transfers. Dough Handling and Processing Lines Common applications include:

- dough transfer

- pastry forming

- chocolate coating lines

✅ PU belts are preferred for their easy-release surface and flexibility PU is also better suited for small pulley diameters, making it ideal for:

- knife-edge conveyors for cookies and small biscuits

- tight transfers into flow-wrapping machines

Dry Product Packaging Zones For baked goods that are cooled and already wrapped: ➡️ PVC rough-top belts are widely used, especially for incline conveyors feeding packaging equipment.

3. Meat, Poultry, and Seafood Processing

Meat and seafood plants represent some of the most demanding sanitary environments due to:

- high levels of oils and fats

- strict contamination control

- frequent cleaning with strong chemicals

Wet Processing and Washdown Zones These areas include:

- trimming lines

- deboning conveyors

- seafood preparation conveyors

✅ PU/TPU belts are the industry standard Advantages include:

- excellent grease and fat resistance

- durability under high-pressure washdown

- longer lifespan when used with scrapers compared to standard PVC

Packaging and Distribution Areas Once products are placed into trays or cartons:

- PVC belts are still commonly used for box handling

- the focus shifts toward throughput and cost efficiency

4. Pharmaceutical and Cosmetics Industry

Although not food-related, pharma and cosmetics require high hygiene standards due to:

- sensitive products

- particle contamination risks

- strict GMP audits

Primary Packaging Areas Examples include:

- blister pack transfer

- bottle filling conveyors

- cosmetic tube handling

✅ Smooth PU belts are often preferred Because they offer:

- low particle shedding

- easy disinfection

- clean surfaces for small, delicate products

Cartoning and Secondary Packaging For boxed products and outer packaging: ➡️ PVC belts provide an effective and economical solution

5. Packaging, Logistics, and Warehouse Operations

In logistics environments, belts rarely touch open products. The priorities are typically:

- high throughput

- abrasion resistance

- cost control

- easy replacement

Common Applications

- parcel sorting conveyors

- incline belt conveyors for cartons

- distribution center transport lines

✅ PVC conveyor belts are the most widely used choice PVC belts also support:

- rough-top surfaces for incline grip

- cleats and sidewalls for angled transfers

- V-guides for stable tracking

Why Production Zones Matter More Than Industry Alone Even within the same industry, belt selection changes depending on the department:

- Primary production (direct contact) → PU/TPU

- Primary packaging (product exposed) → PU or food-grade PVC

- Secondary packaging (product sealed) → PVC

- Warehouse and logistics → PVC

This is why the best belt choice is always based on both industry type and production zone requirements.

Checklist: Selecting the Right Belt Material

Before choosing PVC or PU, consider the following:

- Does the product have direct contact with the belt?

- Are oils, fats, or chemicals involved?

- Is daily washdown or CIP cleaning required?

- Does the conveyor use small pulleys or knife-edge transfers?

- Is incline grip needed through rough-top or cleats?

- Are you optimizing for purchase cost or total cost of ownership (TCO)?

Conclusion: PVC or PU Depends on Industry and Application Zone

There is no single answer for every factory.

- PVC conveyor belts are excellent for packaging, logistics, warehouse handling, and cost-sensitive dry applications.

- PU/TPU conveyor belts are the preferred choice for food processing, pharmaceutical production, hygienic zones, and oily environments.

The most effective approach is to evaluate belt needs through: Industry → Production Zone → Application Requirements

Need Help Choosing the Right Conveyor Belt?

If you want to determine whether PVC or PU belts are best suited for your production line, our team can assist based on:

- your industry sector

- sanitation requirements

- pulley diameter and conveyor design

- cleaning chemicals and washdown routines

- incline, scraper, or tracking needs

📌 Contact us today for a belt conveyor estimate and hygienic belt recommendations.

Connect Automation specializes in providing automation solutions, including conveyor systems, to improve efficiency across various industries. The company delivers cutting-edge technology to help organizations automate tasks and optimize workflows. Connect Automation helps businesses reduce manual efforts, boost productivity, and achieve better outcomes. With a customer-focused approach, the company designs tailored solutions to ensure smooth and effective automation transitions for long-term success.

Kawasan Industri Jababeka Tahap 1, Jl. Jababeka II D Blok C14L Cikarang, Indonesia (17530)

(021) 893 5060 Google Maps

Rungkut Industri III, No. 37, Rungkut Menanggal, Kec. Gn. Anyar Surabaya, Indonesia (60293)

(031) 9985 8624 Google Maps